Mechanical Engineering

We take pride in each and every project we take on

Mechanical Engineering

We take pride in each and every project we take on

Conceptual Analysis

G.L.Tiley & Associates Ltd. Mechanical Engineering department has extensive expertise in the analysis and design of hoist mechanical components. Two such methods are:

Vibration Analyses & Testing:

Our skilled personnel, combined with both commercially available and in-house developed equipment, offers the following advantages:

•Increase hoisting speed by outlining and correcting root causes of high vibration

•Reduce required maintenance through predictive maintenance•Reduce downtime by assessing condition of equipment components during normal operation cycles

•Increase productivity through skip loading and dumping cycles.

Finite Element Analyses & Simulations:

With our specialty in mine hoisting systems, one of our core strengths is finite element analysis and simulations of dynamic systems.

Our Finite Element Analysis Work has:

•demonstrated what loading conditions exist, whereby we have been able to quickly determine the most efficient and cost effective method of repair

•enabled us to calculate deflections in multi-bodied structures both within and outside design limitations

Our Simulations have served to:

•demonstrate and approve heavy lifts, over and above existing equipment's rated capabilities

•outline deficiencies in existing equipment and design improvements

•outline cage motion studies and simulate skip loading and unloading, reducing cycle times.

Design

G.L. Tiley & Associates Ltd. will prepare specifications and designs based upon client requirements and standards, as well as all applicable safety and regulatory standards - including the mining regulations specific to the client locale.

Specifications and Sizing of Components

With our skilled mechanical personnel, we can supply specifications to be able to send out to vendors, outlining performance, shop, documentation and quality requirements, combined with any certifications and testing which are applicable.

At the same time, we can evaluate quotations and will work with our clients to ensure all their requirements are met.

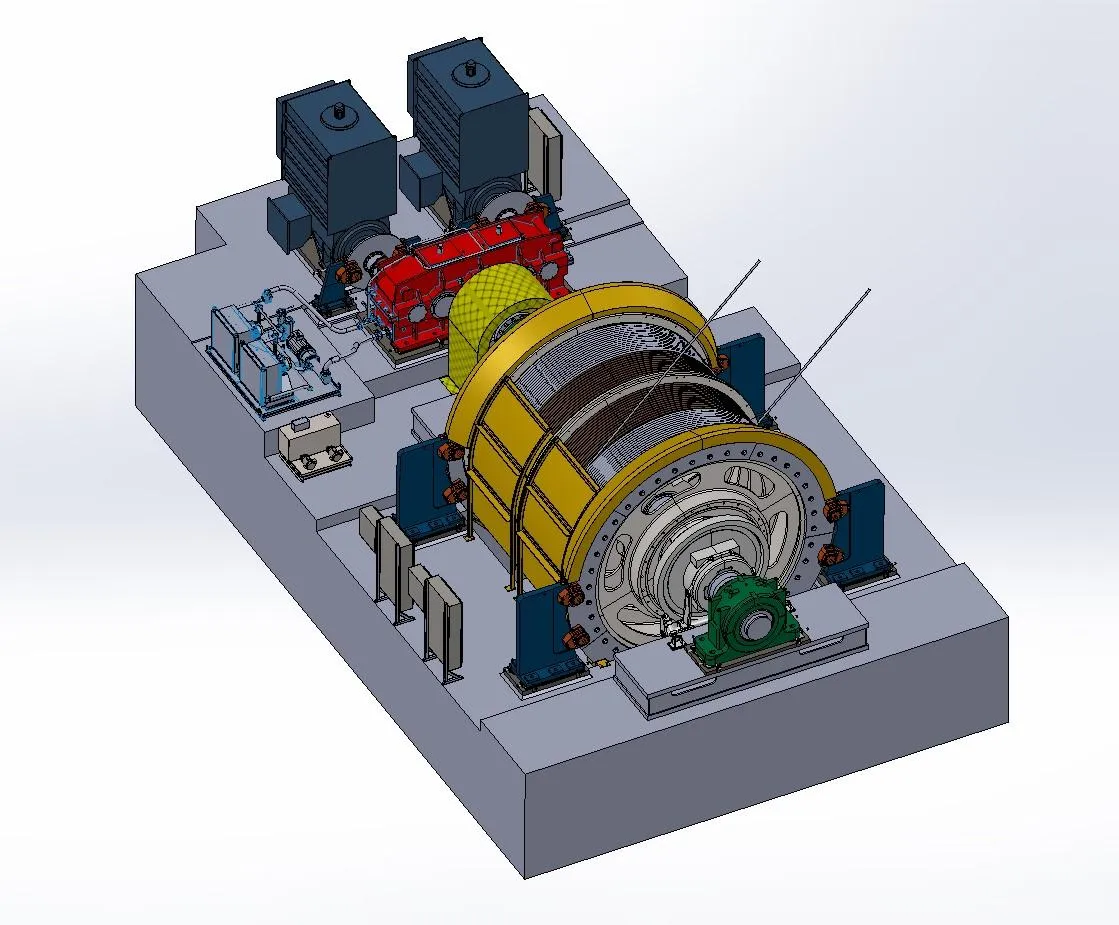

New Hoisting Systems

Throughout our company history, new hoist design has been a cornerstone of our expertise.

We have designed complete hoisting systems, from a 24" single drum winder to complete 16' double drum hoists and some of the largest Koepe hoists in operation.

Our expertise on Blair hoists is one of our specialties: the first Blair hoist in North America was a Tiley design.

Services include:

•complete performance specifications

•construction drawings

•procurement

•quality control and inspections

•installation supervision

•commissioning

•training of personnel

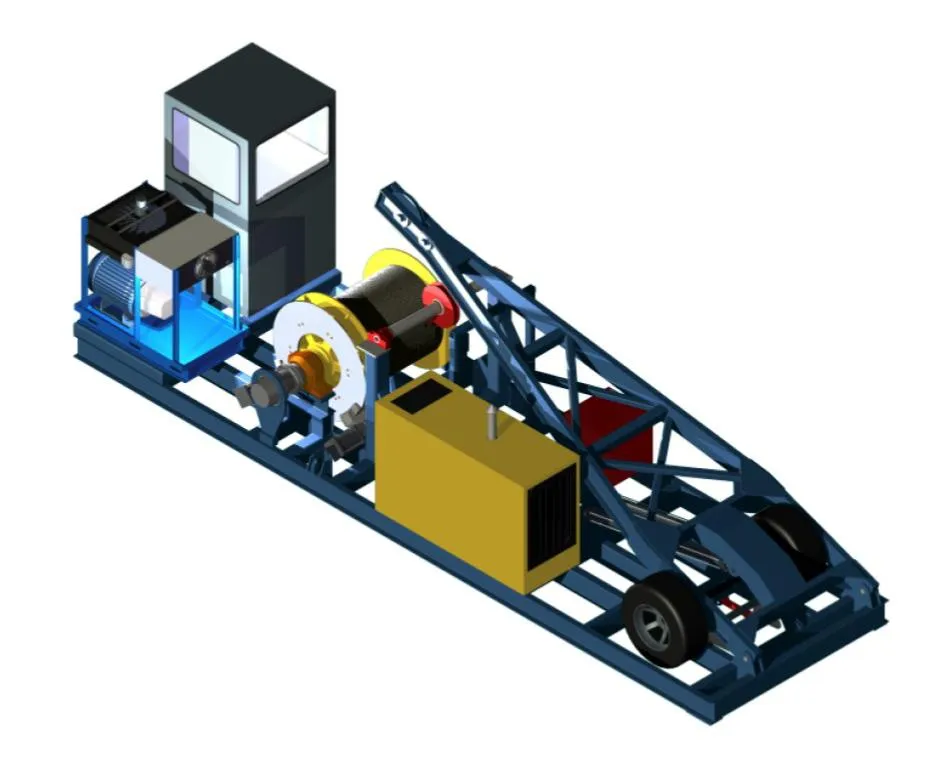

Whether your need is a small mobile emergency hoist or a completely automated production hoist, we have a design aligned with your needs.

With our specialty in mine hoisting systems, one of our core strengths is finite element analysis and simulations of dynamic systems.

Our Finite Element Analysis Work has:

•demonstrated what loading conditions exist, whereby we have been able to quickly determine the most efficient and cost effective method of repair

•enabled us to calculate deflections in multi-bodied structures both within and outside design limitations

Our Simulations have served to:

•demonstrate and approve heavy lifts, over and above existing equipment's rated capabilities

•outline deficiencies in existing equipment and design improvements

•outline cage motion studies and simulate skip loading and unloading, reducing cycle times.

Testing and Inspection

G.L.Tiley & Associates Ltd. maintains an assortment of test and measurement equipment - from digital recorders and transducers to a portable tri-axis decelerometer. These items are available for rent on a weekly or monthly basis as needed by our staff while in the field.

Shaft Guide Alignment

One of the most overlooked maintenance items in an underground hoist is the shaft guide alignment. A misaligned guide not only causes vibrations, but the movement creates wear in the guide system and often is the limitation to higher operational speeds.

This holds true for cable guided systems as well, where misalignment is usually caused by skips passing one another.

G.L Tiley & Associates Ltd. has developed in house shaft alignment measurement equipment, which allows us to determine not only alignment of fixed guides, but cable guides as well. This same equipment enables us to determine the effect of aerodynamics when two or more rope guided skips pass one another, as well as the Coriolis effect, ultimately enabling us to design an efficient and safe shaft design.

Conveyance Freefall Testing

Part of a mine's annual inspections include conveyance freefall testing.

Whether the mine shaft is timber lined, steel lined or cable guided, with hundreds of inspections performed around the globe, we have the expertise and equipment available to ensure safety guidelines are adhered to, and safety features are proven.

Inspection of Exisiting Hoisiting Systems

With our experience on hoists, whether a single drum/double drum, koepe or blair hoist, we can:

•report on the existing condition on the operational or de-commissioned hoist

•recommend and design components for any areas requiring upgrades and/or repairconstruction drawings

•perform hoist incident inspections and report causes for failuresprocurement

•provide certifications on hoists and sheaves where required, even if the original OEM of the equipment is no longer in existence

Stress and Strain Measurement on Hoist Mechanical Components

Regardless of simulations performed on equipment, there is no more accurate data than real world conditions. How a component reacts to a specific load is the ultimate goal. Enter stress and strain measurement.

With years of experience on stress and strain measurement, G.L.Tiley and Associates has used this tool to verify simulations, promote continuous improvement and assess maintenance and production procedures, for improved reliability and increased production rates.

G.L.Tiley & Associates Ltd. Mechanical Engineering department has extensive expertise in the analysis and design of hoist rotating components. Methods include:

Sheave Wheel Analysis

Our mechanical department test and evaluate sheave wheels in the following ways:

•Bicycle type and solid plate spoke sheaves are modeled with finite element analysis software

•High stress locations are identified for fatigue analysis

•Sheaves are certified to working and rope breaking loads

Hoist Drum Analysis

We can model hoist drums with finite element analysis software.

Any high stress locations are identified for fatigue analysis.

Hoists are certified to working and rope breaking loads.

Installation, Commissioning, and Training

As Consulting Engineers, we have supervised hundreds of mechanical installations.

Whether a simple motor installation or alignment of the hoist to Babbitt bearings, our expertise brings experienced installation procedures as well as accurate and complete solutions to any installation concerns.

Without question, having G.L.Tiley & Associates supervise your hoist installation expedites hoist installations, reduces installation costs and provides complete installation planning and scheduling.

Mechanical commissioning brings together the hoist design, installation, and operation of the equipment.

Commissioning completes the hoist supply and setup, and configures the hoist for final operation.

Therefore, it is imperative that this service is performed as accurate and efficiently as possible, as this service will affect the longevity, reliability and performance of the hoist in the long term.

With our in-house and on-site experience in hoist design and operation, combined with the depth of knowledge of G.L.Tiley & Associates and hands-on attitude, we are confident our Commissioning services will provide the most efficient and trouble-free operation for your hoist.

During or after the completion of any project, G.L.Tiley & Associates Ltd. can provide on-site training for hoist operators and maintenance personnel (both electrical and mechanical), including classroom sessions on controls and theory of operation, and hands-on demonstration of inspection and maintenance procedures. Full manuals with component data sheets, maintenance schedules, and complete hoist operator instructions (including HMI control systems) can be prepared and used specifically in these training sessions.

Supervision of Installation:

As Consulting Engineers, we have supervised hundreds of mechanical installations.

Whether a simple motor installation or alignment of the hoist to Babbitt bearings, our expertise brings experienced installation procedures as well as accurate and complete solutions to any installation concerns.

Without question, having G.L.Tiley & Associates Ltd. supervise your hoist installation expedites hoist installations, reduces installation costs and provides complete installation planning and scheduling.

Commissioning:

Mechanical commissioning brings together the hoist design, installation, and operation of the equipment.

Commissioning completes the hoist supply and setup, and configures the hoist for final operation.

Therefore, it is imperative that this service is performed as accurate and efficiently as possible, as this service will affect the longevity, reliability and performance of the hoist in the long term.

With our in-house and on-site experience in hoist design and operation, combined with the depth of knowledge of G.L.Tiley & Associates Ltd. and hands-on attitude, we are confident our Commissioning services will provide the most efficient and trouble-free operation for your hoist.

Conceptual Analysis

G.L.Tiley & Associates Ltd. Mechanical Engineering department has extensive expertise in the analysis and design of hoist mechanical components. Two such methods are:

Vibration Analyses & Testing:

Our skilled personnel, combined with both commercially available and in-house developed equipment, offers the following advantages:

•Increase hoisting speed by outlining and correcting root causes of high vibration

•Reduce required maintenance through predictive maintenance•Reduce downtime by assessing condition of equipment components during normal operation cycles

•Increase productivity through skip loading and dumping cycles.

Finite Element Analyses & Simulations:

With our specialty in mine hoisting systems, one of our core strengths is finite element analysis and simulations of dynamic systems.

Our Finite Element Analysis Work has:

•demonstrated what loading conditions exist, whereby we have been able to quickly determine the most efficient and cost effective method of repair

•enabled us to calculate deflections in multi-bodied structures both within and outside design limitations

Our Simulations have served to:

•demonstrate and approve heavy lifts, over and above existing equipment's rated capabilities

•outline deficiencies in existing equipment and design improvements

•outline cage motion studies and simulate skip loading and unloading, reducing cycle times.

Design

G.L. Tiley & Associates Ltd. will prepare specifications and designs based upon client requirements and standards, as well as all applicable safety and regulatory standards - including the mining regulations specific to the client locale.

Specifications and Sizing of Components

With our skilled mechanical personnel, we can supply specifications to be able to send out to vendors, outlining performance, shop, documentation and quality requirements, combined with any certifications and testing which are applicable.

At the same time, we can evaluate quotations and will work with our clients to ensure all their requirements are met.

New Hoisting Systems

Throughout our company history, new hoist design has been a cornerstone of our expertise.

We have designed complete hoisting systems, from a 24" single drum winder to complete 16' double drum hoists and some of the largest Koepe hoists in operation.

Our expertise on Blair hoists is one of our specialties: the first Blair hoist in North America was a Tiley design.

Services include:

•complete performance specifications

•construction drawings

•procurement

•quality control and inspections

•installation supervision

•commissioning

•training of personnel

Whether your need is a small mobile emergency hoist or a completely automated production hoist, we have a design aligned with your needs.

With our specialty in mine hoisting systems, one of our core strengths is finite element analysis and simulations of dynamic systems.

Our Finite Element Analysis Work has:

•demonstrated what loading conditions exist, whereby we have been able to quickly determine the most efficient and cost effective method of repair

•enabled us to calculate deflections in multi-bodied structures both within and outside design limitations

Our Simulations have served to:

•demonstrate and approve heavy lifts, over and above existing equipment's rated capabilities

•outline deficiencies in existing equipment and design improvements

•outline cage motion studies and simulate skip loading and unloading, reducing cycle times.

Testing and Inspection

G.L.Tiley & Associates Ltd. maintains an assortment of test and measurement equipment - from digital recorders and transducers to a portable tri-axis decelerometer. These items are available for rent on a weekly or monthly basis as needed by our staff while in the field.

Shaft Guide Alignment

One of the most overlooked maintenance items in an underground hoist is the shaft guide alignment. A misaligned guide not only causes vibrations, but the movement creates wear in the guide system and often is the limitation to higher operational speeds.

This holds true for cable guided systems as well, where misalignment is usually caused by skips passing one another.

G.L Tiley & Associates Ltd. has developed in house shaft alignment measurement equipment, which allows us to determine not only alignment of fixed guides, but cable guides as well. This same equipment enables us to determine the effect of aerodynamics when two or more rope guided skips pass one another, as well as the Coriolis effect, ultimately enabling us to design an efficient and safe shaft design.

Conveyance Freefall Testing

Part of a mine's annual inspections include conveyance freefall testing.

Whether the mine shaft is timber lined, steel lined or cable guided, with hundreds of inspections performed around the globe, we have the expertise and equipment available to ensure safety guidelines are adhered to, and safety features are proven.

Inspection of Exisiting Hoisiting Systems

With our experience on hoists, whether a single drum/double drum, koepe or blair hoist, we can:

•report on the existing condition on the operational or de-commissioned hoist

•recommend and design components for any areas requiring upgrades and/or repairconstruction drawings

•perform hoist incident inspections and report causes for failuresprocurement

•provide certifications on hoists and sheaves where required, even if the original OEM of the equipment is no longer in existence

Stress and Strain Measurement on Hoist Mechanical Components

Regardless of simulations performed on equipment, there is no more accurate data than real world conditions. How a component reacts to a specific load is the ultimate goal. Enter stress and strain measurement.

With years of experience on stress and strain measurement, G.L.Tiley and Associates has used this tool to verify simulations, promote continuous improvement and assess maintenance and production procedures, for improved reliability and increased production rates.

G.L.Tiley & Associates Ltd. Mechanical Engineering department has extensive expertise in the analysis and design of hoist rotating components. Methods include:

Sheave Wheel Analysis

Our mechanical department test and evaluate sheave wheels in the following ways:

•Bicycle type and solid plate spoke sheaves are modeled with finite element analysis software

•High stress locations are identified for fatigue analysis

•Sheaves are certified to working and rope breaking loads

Hoist Drum Analysis

We can model hoist drums with finite element analysis software.

Any high stress locations are identified for fatigue analysis.

Hoists are certified to working and rope breaking loads.

Installation, Commissioning, and Training

As Consulting Engineers, we have supervised hundreds of mechanical installations.

Whether a simple motor installation or alignment of the hoist to Babbitt bearings, our expertise brings experienced installation procedures as well as accurate and complete solutions to any installation concerns.

Without question, having G.L.Tiley & Associates supervise your hoist installation expedites hoist installations, reduces installation costs and provides complete installation planning and scheduling.

Mechanical commissioning brings together the hoist design, installation, and operation of the equipment.

Commissioning completes the hoist supply and setup, and configures the hoist for final operation.

Therefore, it is imperative that this service is performed as accurate and efficiently as possible, as this service will affect the longevity, reliability and performance of the hoist in the long term.

With our in-house and on-site experience in hoist design and operation, combined with the depth of knowledge of G.L.Tiley & Associates and hands-on attitude, we are confident our Commissioning services will provide the most efficient and trouble-free operation for your hoist.

During or after the completion of any project, G.L.Tiley & Associates Ltd. can provide on-site training for hoist operators and maintenance personnel (both electrical and mechanical), including classroom sessions on controls and theory of operation, and hands-on demonstration of inspection and maintenance procedures. Full manuals with component data sheets, maintenance schedules, and complete hoist operator instructions (including HMI control systems) can be prepared and used specifically in these training sessions.

Supervision of Installation:

As Consulting Engineers, we have supervised hundreds of mechanical installations.

Whether a simple motor installation or alignment of the hoist to Babbitt bearings, our expertise brings experienced installation procedures as well as accurate and complete solutions to any installation concerns.

Without question, having G.L.Tiley & Associates Ltd. supervise your hoist installation expedites hoist installations, reduces installation costs and provides complete installation planning and scheduling.

Commissioning:

Mechanical commissioning brings together the hoist design, installation, and operation of the equipment.

Commissioning completes the hoist supply and setup, and configures the hoist for final operation.

Therefore, it is imperative that this service is performed as accurate and efficiently as possible, as this service will affect the longevity, reliability and performance of the hoist in the long term.

With our in-house and on-site experience in hoist design and operation, combined with the depth of knowledge of G.L.Tiley & Associates Ltd. and hands-on attitude, we are confident our Commissioning services will provide the most efficient and trouble-free operation for your hoist.

Looking for rock solid engineering expertise on your next hoist project?

Looking for rock solid engineering expertise on your next hoist project?