Electrical Engineering

We take pride in each and every project we take on

Electrical Engineering

Meet our Mechanical engineering team

Conceptual Analysis

G.L.Tiley & Associates Ltd. Electrical Engineering department has extensive expertise in the analysis and design of hoist electrical components. Methods include:

Evaluate Existing Hoist Electric Control and Safety

Our electrical staff can test and evaluate exisiting hoist control systems of all vintages, reviewing functionality, reliability, and compliance with regulatory bodies.

Evaluate Existing AC and DC Drives

We can inspect and evaulaute existing AC and DC drive systems, including motors, as well as breakers and contactors. This analysis would include a review of reliability,

availability of spare parts, and upgrade potential using any existing components.

G.L.Tiley & Associates Ltd. can also assist with the location or construction of spare components for legacy equipment.

Provide Upgrade and Retrofit Solutions

For over 40 years, G.L.Tiley & Associates Ltd. has focused on the upgrade and retrofit market for hoist components, providing solutions which are both more timely and more cost-effective.

Our proven track record with experienced vendors provides for economical, efficient upgrades allowing for years of reliable operation using proven, modern components.

Design

G.L. Tiley & Associates Ltd. will handle all elements of electrical design in the hoist control system.

Building Services amd Power Distribution

Our electrical engineering expertise extends beyond the realm of control systems and hoist drives – G.L.Tiley &; Associates Ltd. can provide the full electrical design for mining applications. This includes power distribution and substation design, MCC layout and cable sizing, building services, lighting, grounding, and lightning protection.

With the assistance of other experts, we can provide measurement and analysis of power systems, providing a full study of existing and proposed loads, and recommendations for modernization and increases in capacity, as well as power factor correction for DC drive systems.

Digital Hoist Supervisor (DHS) Hoist Overtravel and Overspeed Protection System

The advent of PLC controls in mine hoisting resulted in the development of the Digital Hoist Supervisor, or DHS, a modernization of the classic mechanical Lilly controller. A system of redundant PLCs and position encoders provides overspeed and overtravel protection for all positions in the shaft, for all types of hoists. The Tiley DHS is also self-monitoring and provides more operational data (through an HMI interface) to the operator for troubleshooting of faults. The DHS may be integrated with a new Tiley hoist control system, or as a stand-alone retrofit to an existing hoist control system. Regulatory approved since 1996 in Ontario, the DHS has been installed in Canada, the USA, Venezuela, Peru, Spain, and Brazil.

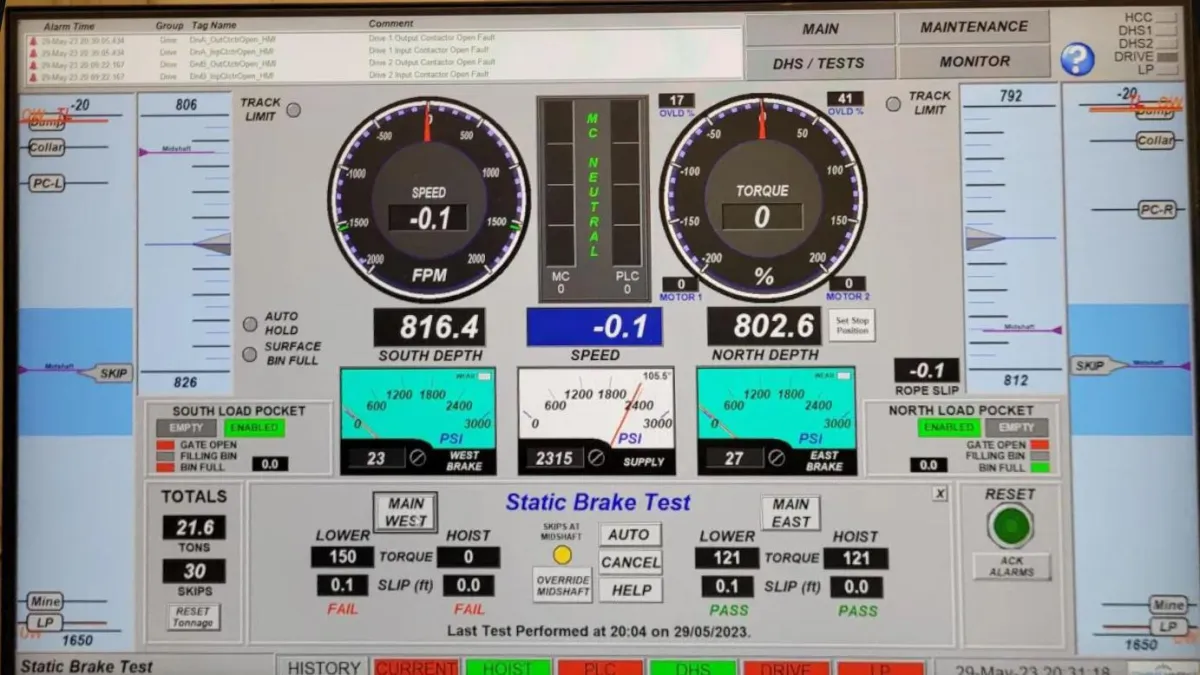

HMI User Interface

Hand-in-hand with our pioneering use of PLC controls, G.L.Tiley & Associates Ltd. was an early adherent to using PC-based HMI (Human-Machine-Interface) systems for mine hoist controls, providing detailed, real-time hoist and drive data to the hoist operator, as well as historical logging of faults and hoist performance. We are also using small touch-screen HMI displays in exposed locations, where practical.

Multi-Level Service Hoist Automation

Multi-level service hoists (and combined function service/production hoists) are another of G.L.Tiley & Associates Ltd. hallmark product. Shaft-station control provides for hoisting systems from two to twenty levels, or more, including multi-deck cages and specialized functions such as automatic chairing or control from inside the cage. A variety of control options are available and the final custom design will meet the specific needs of any client, including safety, ease of use, and regulatory compliance.

PLC-Based Brake Regulator

A regulated, redundant PLC-based brake regulator system can be integrated with a Tiley PLC-based hoist control system, or set up as a stand-alone system on all types of brake systems. Duplicate PLCs and sensors provide repeatable emergency brake control to a target deceleration rate, regardless of hoist configuration, speed, direction, or payload. This feature can be retrofitted to existing brake systems, as well as new brake controls.

PLC Systems

Since their acceptance in mining, G.L.Tiley & Associates Ltd. has been a pioneer in the use of PLC control systems for mine hoist applications, providing advanced control for manual, shaft-sinking, and automated operation of both production and service hoists, loading pocket and material handling systems.Troubleshooting and reliability are far beyond the alternatives, and the use of readily available off-the-shelf PLC components ensures a long product life. At present, we are using both Modicon and Rockwell PLC systems to provide the highest levels of functionality and control sophistication.

Production Hoist Automation

Automated production hoists, with an optimized duty cycle, provide the highest levels of tonnage with consistent, reliable operation. We are able to interface with loading pocket controls designed in house, or by others. Data logging of production statistics is also available.

Specifications and Material Estimates

G.L.Tiley & Associates Ltd. will prepare full specifications for each project, allowing for easy compilation of recommended spare parts. Material estimates for installations can be provided to installers for quicker and more accurate estimates of construction.

Testing and Inspection

G.L.Tiley & Associates Ltd. maintains an assortment of test and measurement equipment - from digital recorders and transducers to a portable tri-axis decelerometer. These items are available for rent on a weekly or monthly basis as needed by our staff while in the field.

Inspect and Test AC and DC Machines

G.L.Tiley & Associates Ltd. has over 40 years of expertise with rotating machines of all types and sizes, and can perform in-situ inspection and testing, or facilitate shop testing of AC and DC motors and generators. Furthermore, we can provide supervision of repair and refurbishing, regardless of location.

Test and Verify Hoist Safety Circuits

Our engineers can perform testing and analysis of existing hoist control systems, for safety, reliability, and regulatory compliance, especially for facilities in the process of re-opening or modernizing. These tests can be performed quickly, safely, and with minimal disruption to normal hoist operation.

Test Hoist Control Performance

As with the testing and verification of existing hoist control systems, the engineers at G.L.Tiley Associates Ltd. can test the performance of hoist control systems, analyze and optimize hoist duty cycles and provide recommendations on modernization based upon existing capability and future production targets.

Installation, Commissioning, and Training

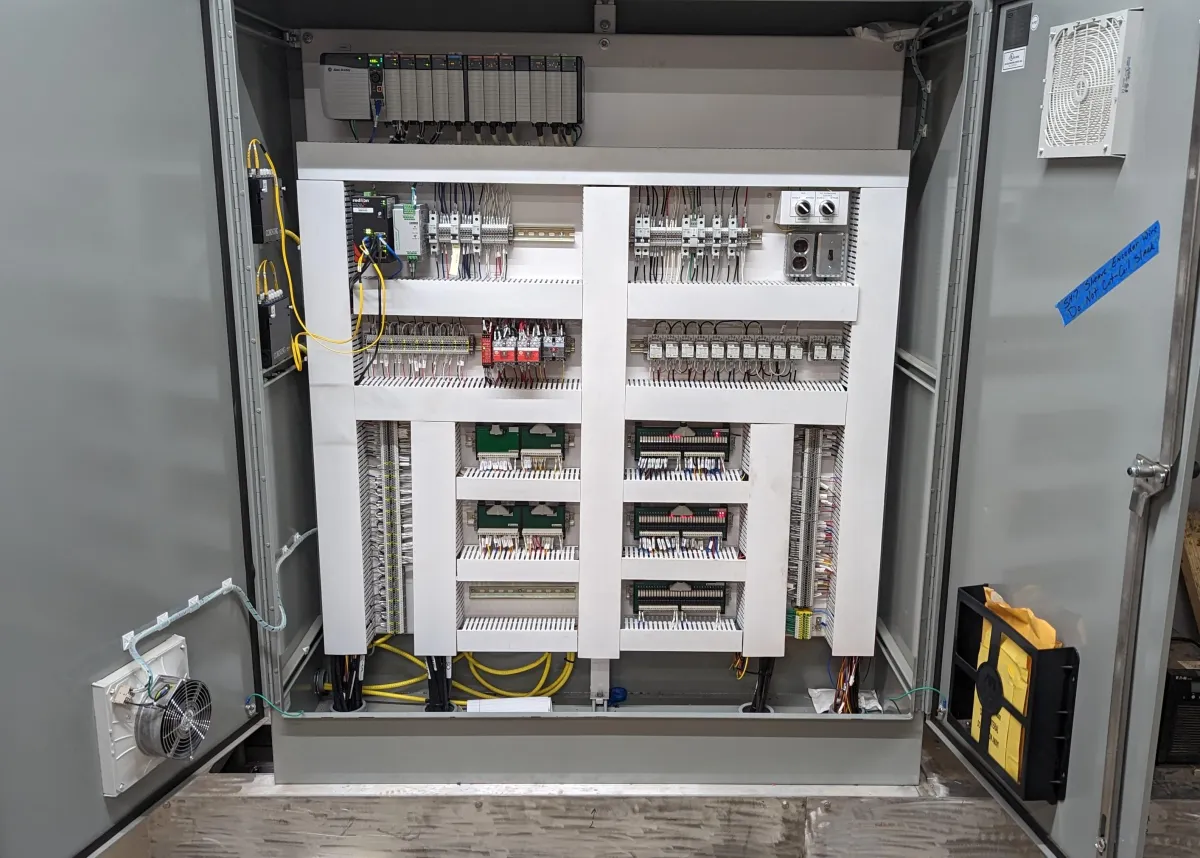

Electrical Panel Design and Inspection:

Our engineers provide full and complete designs of all electrical panels, with construction by trusted and experienced local constructors.

This facilitates immediate and continuing communication with the builder, with full inspection and shop-testing prior to shipping, ensuring zero defects in delivered products.

Provide Schematics and Interconnection Diagrams:

All hoist installations will have complete electrical schematics, interconnection diagrams, and cable schedules, all in an easy-to-read standard format. Multiple hoist installations at the same site will be as similar as possible, ensuring maximum symmetry and ease of familiarization. As-built and updated schematics are provided in Adobe PDF format, which facilitates viewing and printing by any computer user. (Other formats are available by mutual agreement between the client and G.L.Tiley & Associates Ltd.) Our standard schematics usually result in 100% error-free installation, even when the installers native language is not English.

Provide Site Support:

As Consulting Engineers, we have supervised hundreds of electrical installations. G.L. Tiley & Associates Ltd. engineers are well versed in providing site support during the installation of hoist control systems, including pre-commissioning checks and technical advice to installers and permanent mine staff, ensuring a smooth transition from construction to ownership and operation.

Commission Complete Hoist Control System:

Commissioning by our veteran engineering staff ensures that our designs work as intended, and specific custom modifications are addressed as necessary. New installation or retrofit, production or service hoist, shaft-sinking or normal operation, we have the experience of hundreds of hoists behind us. Our senior staff is committed, focused, and thoroughly familiar with the organizational and troubleshooting techniques necessary for successful commissioning.

Training:

During or after the completion of any project, G.L.Tiley & Associates Ltd. can provide on-site training for hoist operators and maintenance personnel (both electrical and mechanical), including classroom sessions on controls and theory of operation, and hands-on demonstration of inspection and maintenance procedures. Full manuals with component data sheets, maintenance schedules, and complete hoist operator instructions (including HMI control systems) can be prepared and used specifically in these training sessions.

Looking for rock solid engineering expertise on your next hoist project?

Conceptual Analysis

G.L.Tiley & Associates Ltd. Electrical Engineering department has extensive expertise in the analysis and design of hoist electrical components. Methods include:

Evaluate Existing Hoist Electric Control and Safety

Our electrical staff can test and evaluate exisiting hoist control systems of all vintages, reviewing functionality, reliability, and compliance with regulatory bodies.

Evaluate Existing AC and DC Drives

We can inspect and evaulaute existing AC and DC drive systems, including motors, as well as breakers and contactors. This analysis would include a review of reliability,

availability of spare parts, and upgrade potential using any existing components.

G.L.Tiley & Associates Ltd. can also assist with the location or construction of spare components for legacy equipment.

Provide Upgrade and Retrofit Solutions

For over 40 years, G.L.Tiley & Associates Ltd. has focused on the upgrade and retrofit market for hoist components, providing solutions which are both more timely and more cost-effective.

Our proven track record with experienced vendors provides for economical, efficient upgrades allowing for years of reliable operation using proven, modern components.

Design

G.L. Tiley & Associates Ltd. will handle all elements of electrical design in the hoist control system.

Building Services amd Power Distribution

Our electrical engineering expertise extends beyond the realm of control systems and hoist drives – G.L.Tiley &; Associates Ltd. can provide the full electrical design for mining applications. This includes power distribution and substation design, MCC layout and cable sizing, building services, lighting, grounding, and lightning protection.

With the assistance of other experts, we can provide measurement and analysis of power systems, providing a full study of existing and proposed loads, and recommendations for modernization and increases in capacity, as well as power factor correction for DC drive systems.

Digital Hoist Supervisor (DHS) Hoist Overtravel and Overspeed Protection System

The advent of PLC controls in mine hoisting resulted in the development of the Digital Hoist Supervisor, or DHS, a modernization of the classic mechanical Lilly controller. A system of redundant PLCs and position encoders provides overspeed and overtravel protection for all positions in the shaft, for all types of hoists. The Tiley DHS is also self-monitoring and provides more operational data (through an HMI interface) to the operator for troubleshooting of faults. The DHS may be integrated with a new Tiley hoist control system, or as a stand-alone retrofit to an existing hoist control system. Regulatory approved since 1996 in Ontario, the DHS has been installed in Canada, the USA, Venezuela, Peru, Spain, and Brazil.

HMI User Interface

Hand-in-hand with our pioneering use of PLC controls, G.L.Tiley & Associates Ltd. was an early adherent to using PC-based HMI (Human-Machine-Interface) systems for mine hoist controls, providing detailed, real-time hoist and drive data to the hoist operator, as well as historical logging of faults and hoist performance. We are also using small touch-screen HMI displays in exposed locations, where practical.

Multi-Level Service Hoist Automation

Multi-level service hoists (and combined function service/production hoists) are another of G.L.Tiley & Associates Ltd. hallmark product. Shaft-station control provides for hoisting systems from two to twenty levels, or more, including multi-deck cages and specialized functions such as automatic chairing or control from inside the cage. A variety of control options are available and the final custom design will meet the specific needs of any client, including safety, ease of use, and regulatory compliance.

PLC-Based Brake Regulator

A regulated, redundant PLC-based brake regulator system can be integrated with a Tiley PLC-based hoist control system, or set up as a stand-alone system on all types of brake systems. Duplicate PLCs and sensors provide repeatable emergency brake control to a target deceleration rate, regardless of hoist configuration, speed, direction, or payload. This feature can be retrofitted to existing brake systems, as well as new brake controls.

PLC Systems

Since their acceptance in mining, G.L.Tiley & Associates Ltd. has been a pioneer in the use of PLC control systems for mine hoist applications, providing advanced control for manual, shaft-sinking, and automated operation of both production and service hoists, loading pocket and material handling systems.Troubleshooting and reliability are far beyond the alternatives, and the use of readily available off-the-shelf PLC components ensures a long product life. At present, we are using both Modicon and Rockwell PLC systems to provide the highest levels of functionality and control sophistication.

Production Hoist Automation

Automated production hoists, with an optimized duty cycle, provide the highest levels of tonnage with consistent, reliable operation. We are able to interface with loading pocket controls designed in house, or by others. Data logging of production statistics is also available.

Specifications and Material Estimates

G.L.Tiley & Associates Ltd. will prepare full specifications for each project, allowing for easy compilation of recommended spare parts. Material estimates for installations can be provided to installers for quicker and more accurate estimates of construction.

Testing and Inspection

G.L.Tiley & Associates Ltd. maintains an assortment of test and measurement equipment - from digital recorders and transducers to a portable tri-axis decelerometer. These items are available for rent on a weekly or monthly basis as needed by our staff while in the field.

Inspect and Test AC and DC Machines

G.L.Tiley & Associates Ltd. has over 40 years of expertise with rotating machines of all types and sizes, and can perform in-situ inspection and testing, or facilitate shop testing of AC and DC motors and generators. Furthermore, we can provide supervision of repair and refurbishing, regardless of location.

Test and Verify Hoist Safety Circuits

Our engineers can perform testing and analysis of existing hoist control systems, for safety, reliability, and regulatory compliance, especially for facilities in the process of re-opening or modernizing. These tests can be performed quickly, safely, and with minimal disruption to normal hoist operation.

Test Hoist Control Performance

As with the testing and verification of existing hoist control systems, the engineers at G.L.Tiley Associates Ltd. can test the performance of hoist control systems, analyze and optimize hoist duty cycles and provide recommendations on modernization based upon existing capability and future production targets.

Installation, Commissioning, and Training

Electrical Panel Design and Inspection:

Our engineers provide full and complete designs of all electrical panels, with construction by trusted and experienced local constructors.

This facilitates immediate and continuing communication with the builder, with full inspection and shop-testing prior to shipping, ensuring zero defects in delivered products.

Provide Schematics and Interconnection Diagrams:

All hoist installations will have complete electrical schematics, interconnection diagrams, and cable schedules, all in an easy-to-read standard format. Multiple hoist installations at the same site will be as similar as possible, ensuring maximum symmetry and ease of familiarization. As-built and updated schematics are provided in Adobe PDF format, which facilitates viewing and printing by any computer user. (Other formats are available by mutual agreement between the client and G.L.Tiley & Associates Ltd.) Our standard schematics usually result in 100% error-free installation, even when the installers native language is not English.

Provide Site Support:

As Consulting Engineers, we have supervised hundreds of electrical installations. G.L. Tiley & Associates Ltd. engineers are well versed in providing site support during the installation of hoist control systems, including pre-commissioning checks and technical advice to installers and permanent mine staff, ensuring a smooth transition from construction to ownership and operation.

Commission Complete Hoist Control System:

Commissioning by our veteran engineering staff ensures that our designs work as intended, and specific custom modifications are addressed as necessary. New installation or retrofit, production or service hoist, shaft-sinking or normal operation, we have the experience of hundreds of hoists behind us. Our senior staff is committed, focused, and thoroughly familiar with the organizational and troubleshooting techniques necessary for successful commissioning.

Training:

During or after the completion of any project, G.L.Tiley & Associates Ltd. can provide on-site training for hoist operators and maintenance personnel (both electrical and mechanical), including classroom sessions on controls and theory of operation, and hands-on demonstration of inspection and maintenance procedures. Full manuals with component data sheets, maintenance schedules, and complete hoist operator instructions (including HMI control systems) can be prepared and used specifically in these training sessions.

Looking for rock solid engineering expertise on your next hoist project?